December sales reward short attention spans. Sequins move. Red tags clear inventory. But once the rush quiets, unsold units start weighing differently… on shelves, in spreadsheets, and on next quarter’s plans.

That’s where many fashion labels feel the pinch. They stocked for gifting but never planned for what comes after. Sell-through slows. Markdowns pile up.

The gap isn’t demand; it’s design. Some pieces carry better into January because they were built that way from the start.

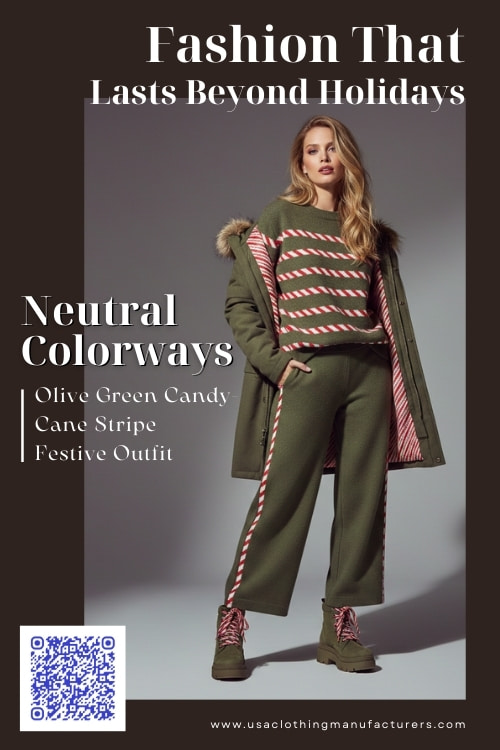

Holiday patterns tend to lock you in. Plaids, novelty graphics, or overt seasonal palettes create a short shelf life. Once the holiday clock runs out, those styles begin to look dated (regardless of how wearable they actually are).

Instead, lines that lean on tonal layering (think camel, charcoal, olive, or off-white) stretch farther. These colors feel intentional in December and still relevant weeks later. The same applies to patterns. Subtle herringbones or tight checks hold their value better than candy-cane stripes or oversized slogans.

When working with retail buyers or private label partners, we’ve seen more consistent sell-through when seasonal capsules anchor around neutrals with just a hint of festive overlay.

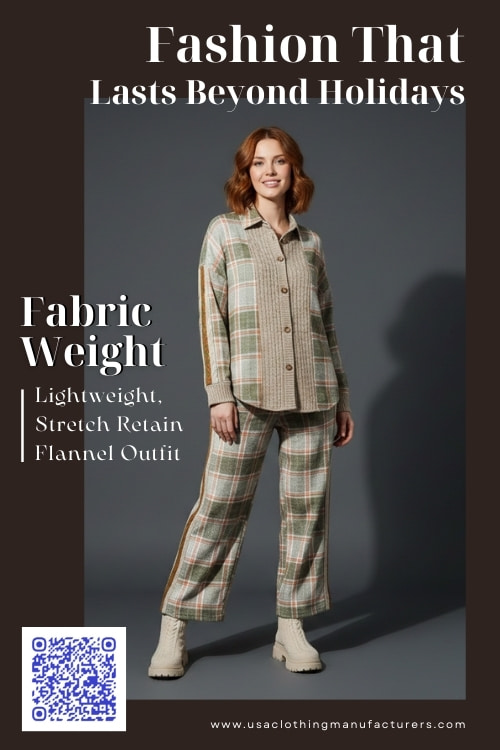

Heavy-gauge knits and brushed jerseys do more than keep people warm. They communicate purpose. Holiday buyers often reach for comfort, but many of them continue wearing those pieces deep into Q1 if the materials allow it.

This is where timing and sourcing intersect. Lightweight fabrics in deep winter drop-offs often stall post-New Year. Flannel, French terry, corduroy, or structured fleece give the product more utility, whether it was gifted or self-bought.

Finishes matter too. Pieces that resist pilling or stretching retain their shape across multiple washes, giving customers a reason to return for more or to keep wearing what they received.

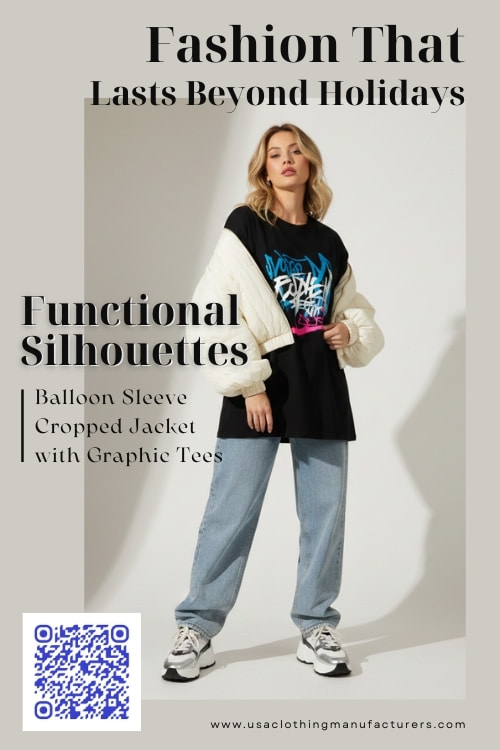

Fashion trends spike fast around holidays. Cropped jackets, novelty trims, balloon sleeves, or oversized graphics tend to catch attention. But after January 1st, shoppers revert to fit, comfort, and repeat wear.

Retailers who balance trend and utility (like offering both cropped sweaters and full-length options in the same drop) often reduce their need for markdowns. Classic cuts that layer easily or can transition from casual to workwear extend the product’s relevance.

When your fit decisions account for temperature shifts, layering, and multi-scenario use, your inventory works longer than the gifting window.

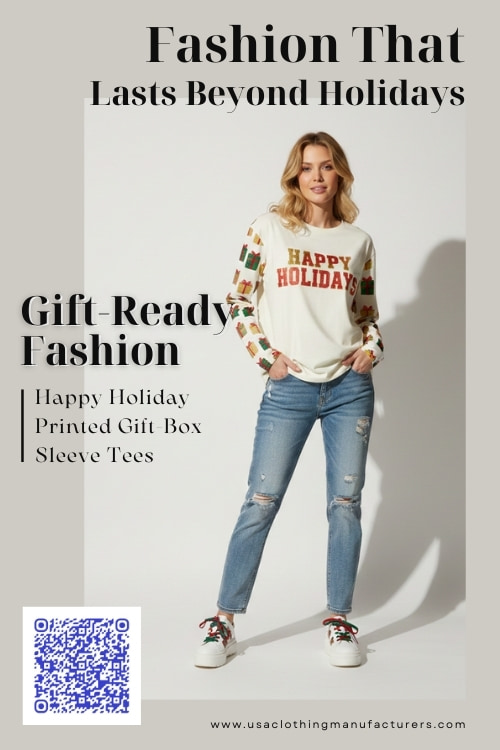

Giftability drives a lot of Q4 design. But “giftable” doesn’t have to mean disposable.

Products that pack well, come in clean packaging, and suit a wide range of body types or age groups tend to win gifting decisions. But they also continue selling later, especially if the recipient finds them wearable in regular routines.

We’ve worked on apparel lines that included optional gift-box sleeves without locking the product into holiday-specific colors. That flexibility supported both December sell-through and January repeat orders.

Small design decisions around tags, trims, and care instructions often affect how a product lives beyond the holiday season.

Heat-transfer tags, understated branding, and simple washing instructions can increase the odds of daily wear. Loud brand tags, oversized hangers, or one-time seasonal graphics can make the piece feel like an occasion-only product—even when the materials are solid.

Buyers in January often lean toward comfort and ease. A piece that quietly blends into routine dressing habits gets worn more and reordered faster. Internal team discussions at USA Clothing Manufacturers often come back to this: if the unboxing experience feels universal, the product avoids the “expired” tag post December.

Designing for January starts at the sampling stage. Whether you’re building a full line or a seasonal capsule, these details help shape carryover success:

Your factory or supplier should be aligned with these markers. When design, sourcing, and finish all align with multi-month usability, you spend less time dealing with stalled SKUs.

The rush may feel chaotic, but patterns repeat. Look at last year’s holiday lines; what carried over into January? What got returned? What had the highest second-week sell-through?

Many brands stop analysis at “what moved fastest.” But the more useful question is “what held value into the next quarter?” Sometimes it’s the basic hoodie with a better neckline. Sometimes it’s the relaxed pants that hit just the right taper.

When your December assortment includes at least a few intentionally evergreen styles, you’re better prepared for post-holiday momentum. That reduces clearance stress and builds a stronger baseline for your next year’s planning.

The most successful fashion pieces of Q4 don’t just sell, they stay worn. That only happens when design and timing account for both the gift moment and the months that follow.

At USA Clothing Manufacturers, we collaborate with retail and private label clients to shape wholesale collections that bridge this gap. Our teams pay close attention to fabric longevity, fit logic, and finish quality, not just for December stock-in but for January sell-through.

If you’re planning your next drop, start with this in mind: what will still feel right once the tree comes down?